FTC will provide experienced staff to attend to your project needs in a highly responsive manner. We provide services from project conception, design, construction and long-term monitoring. Some of our key services include:

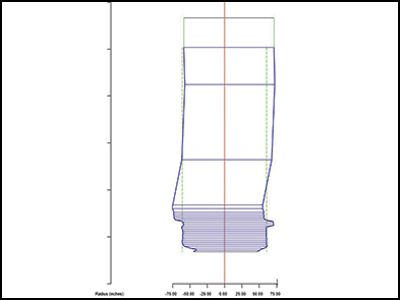

● Cross-hole sonic logging (CSL) of drilled shafts

● Thermal Integrity Profiling (T.I.P) testing of drilled shafts and cast-in-place piles

● Dynamic pile testing

● Camera observation

● Vibration monitoring

● Construction observation

● Geotechnical investigation services

● Pre-construction phase pile foundation constructability review

● Design and installation of geotechnical instrumentation systems

● Forensic engineering

● Expert witness/litigation support